Mining

Tuesday, September 13th, 2022 6:06 am EDT

Named in honour of pioneering British crystallographer Dame Kathleen Lonsdale, lonsdaleite is a rare, hexagonal-shaped diamond believed to be stronger and harder than its more typical cubic cousin. Its existence, however, has been a controversial topic among researchers.

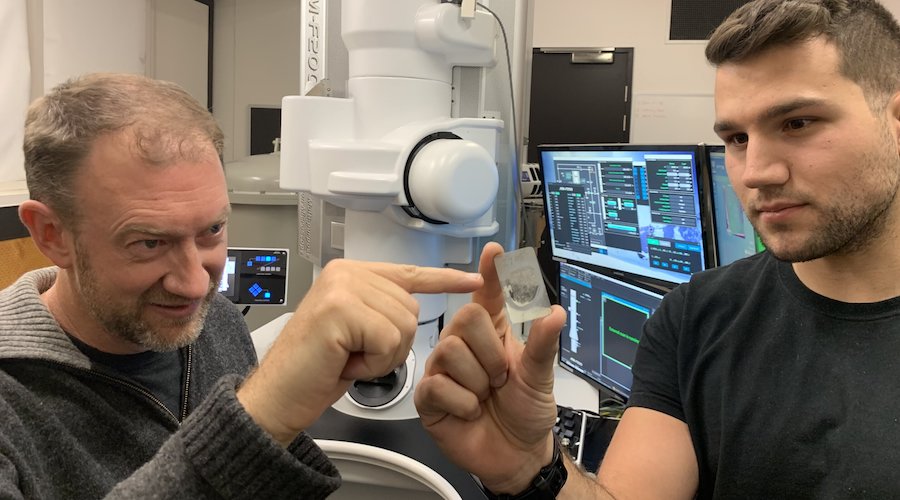

But by using a range of cutting-edge science techniques on the largest sample of ureilite meteorites to date, the new study provides clear evidence of lonsdaleite’s formation in nature, offering clues to its synthetic production.

“If something that’s harder than diamond can be manufactured readily, that’s something industry would want to know about,” Colin MacRae, one of the scientists involved in the paper, said.

How lonsdaleite is created

The study, which was led by geology professor Andy Tomkins from Monash University, reveals a novel process in which the lonsdaleite was created following the collision of the dwarf planet with a large asteroid about 4.5 billion years ago. This led to the replacement of graphite crystals in the dwarf planet’s mantle facilitated by a super-hot fluid as it cools and decompresses.

“We propose that lonsdaleite in the meteorites formed from a supercritical fluid at high temperature and moderate pressures, almost perfectly preserving the textures of the pre-existing graphite,” Tomkins said. “Later, lonsdaleite was partially replaced by diamond as the environment cooled and the pressure decreased.”

In other words, the parent asteroid was catastrophically disrupted by a giant impact while the mantle was still very hot, creating the ideal conditions for lonsdaleite and then diamond growth as the pressure and temperature decreased in a fluid and gas-rich environment.

“Nature has thus provided us with a process to try and replicate in industry,” Tomkins said. “We think that lonsdaleite could be used to make tiny, ultra-hard machine parts if we can develop an industrial process that promotes the replacement of pre-shaped graphite parts by lonsdaleite.”

This post has been syndicated from a third-party source. View the original article here.