Mining

Tuesday, August 30th, 2022 6:06 am EDT

In a paper published in the journal Nature, the researchers explain that the new battery architecture uses aluminum and sulphur as its two electrode materials.

“I wanted to invent something that was better, much better, than lithium-ion batteries for small-scale stationary storage, and ultimately for automotive [uses],” Donald Sadoway, lead author of the study, said in a media statement.

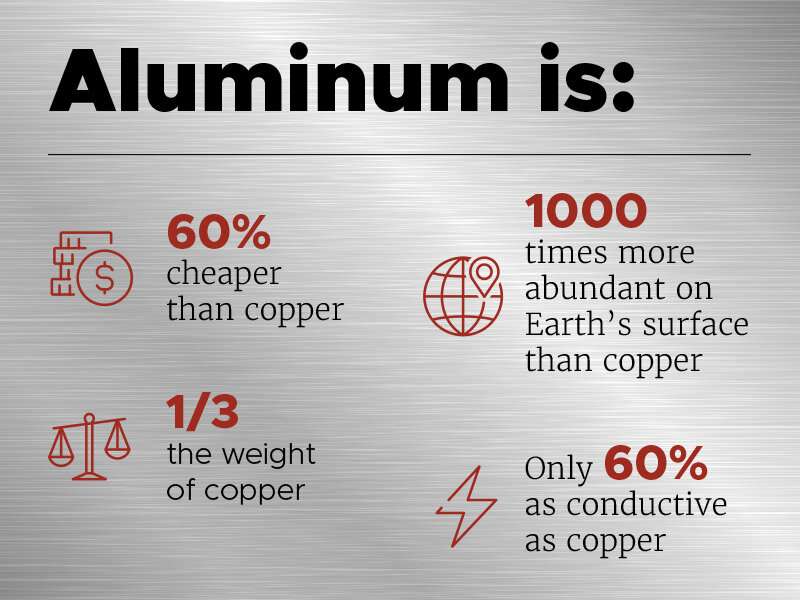

In addition to being expensive, lithium-ion batteries contain a flammable electrolyte, making them less than ideal for transportation. So, Sadoway started studying the periodic table, looking for cheap, abundant metals that might be able to substitute for lithium.

The commercially dominant metal, iron, doesn’t have the right electrochemical properties for an efficient battery. But the second-most-abundant metal in the marketplace — and actually the most abundant metal on earth — is aluminum.

“So, I said, well, let’s just make that a bookend. It’s gonna be aluminum,” Sadoway said.

Then came deciding what to pair the aluminum with for the other electrode, and what kind of electrolyte to put in between to carry ions back and forth during charging and discharging.

The cheapest of all the non-metals is sulphur, so that became the second electrode material. As for the electrolyte, “we were not going to use the volatile, flammable organic liquids that have sometimes led to dangerous fires in cars and other applications of lithium-ion batteries,” Sadoway said.

Thus, he and his team tried some polymers but ended up looking at a variety of molten salts that have relatively low melting points — close to the boiling point of water, as opposed to nearly 1,000 degrees Fahrenheit for many salts and therefore don’t require special insulation and anticorrosion measures.

Cheap ingredients

The three ingredients they ended up with are cheap and readily available — aluminum, no different from the foil at the supermarket; sulphur, which is often a waste product from processes such as petroleum refining; and widely available salts.

“The ingredients are cheap, and the thing is safe — it cannot burn,” Sadoway said.

In their experiments, the team showed that the battery cells could endure hundreds of cycles at exceptionally high charging rates, with a projected cost per cell of about one-sixth that of comparable lithium-ion cells. They also demonstrated that the charging rate was highly dependent on the working temperature, with 110 degrees Celsius showing 25 times faster rates than 25 C.

Surprisingly, the molten salt the team chose as an electrolyte simply because of its low melting point turned out to have a fortuitous advantage. One of the biggest problems in battery reliability is the formation of dendrites but this particular salt, it happens, is very good at preventing that malfunction.

“We did experiments at very high charging rates, charging in less than a minute, and we never lost cells due to dendrite shorting,” Sadoway said.

The battery requires no external heat source to maintain its operating temperature. The heat is naturally produced electrochemically by the charging and discharging of the battery.

“As you charge, you generate heat, and that keeps the salt from freezing. And then, when you discharge, it also generates heat,” Sadoway noted.

In a typical installation used for load-levelling at a solar generation facility, for example, “you’d store electricity when the sun is shining, and then you’d draw electricity after dark, and you’d do this every day. And that charge-idle-discharge-idle is enough to generate enough heat to keep the thing at temperature.”

In the researcher’s view, this new battery formulation would be ideal for installations of about the size needed to power a single home or small to medium business, producing on the order of a few tens of kilowatt-hours of storage capacity.

The smaller scale of the aluminum-sulphur batteries would also make them practical for uses such as electric vehicle charging stations.

Sadoway pointed out that when electric vehicles become common enough on the roads that several cars want to charge up at once, having a battery system such as this to store power and then release it quickly when needed could eliminate the need for installing expensive new power lines to serve these chargers.

The new technology is already the basis for a company called Avanti, which has licensed the patents to the system.

“The first order of business for the company is to demonstrate that it works at scale,” Sadoway said.

This post has been syndicated from a third-party source. View the original article here.